ECNC 10080 M

SOFT-METALS MILLING MACHINE

Wet Processing

Dry

Milling

Temperature Control

12mm Max Dia

Vacuum Table

Touch Screen

4th Axis

Servo Motor Upgrade

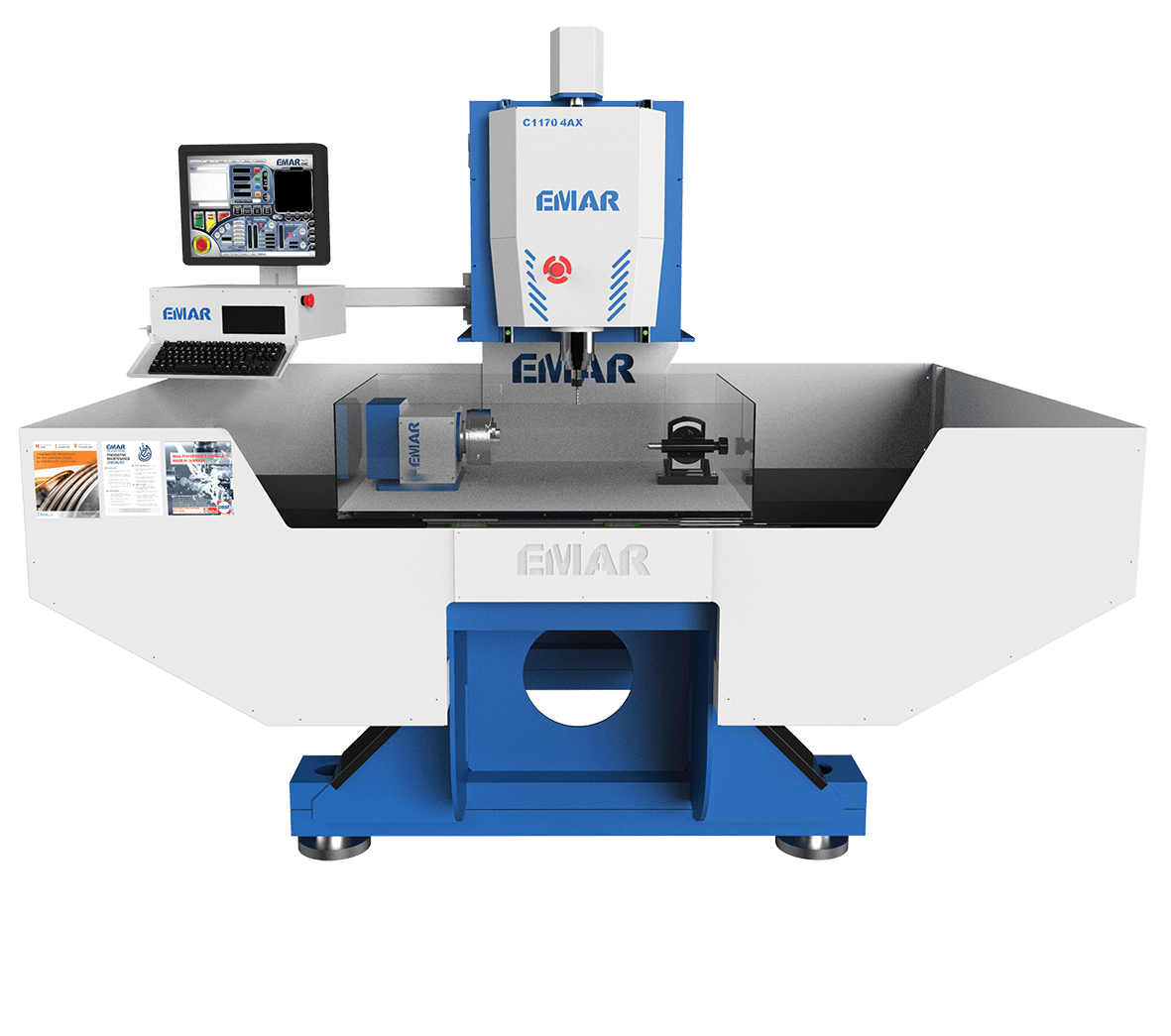

ECNC 10080 M

HIGHLIGHTS

MACH-3 CONTROL

Mach-3 interactive

User friendly control

BUILT-UP SECTION CHASSIS

Optimum efficiency

Highest performance to price ratio

HIGH-QUALITY COMPONENTS

Leading linear and

bearing components

4 AXIS SIMULTANEOUS

MACHINING

High-precision

4-axis rotary

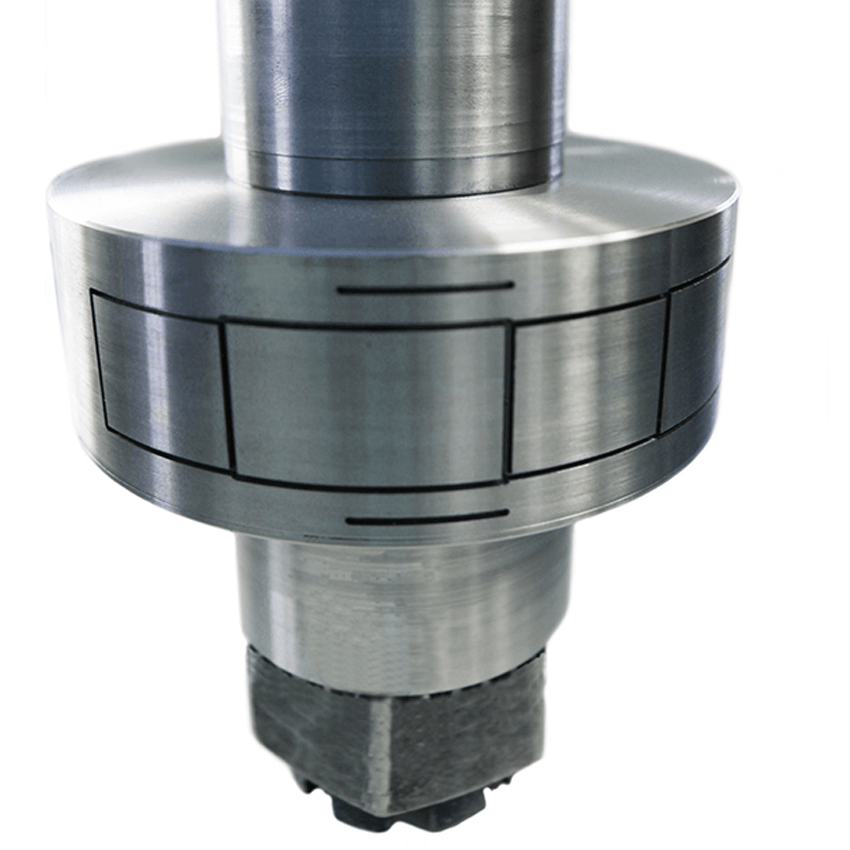

WATER

COOLED SPINDLE

3.0 kW 24k.RPM high speed spindle

for precise results with optimum finish

DURABLE

AROUND THE CLOCK

Non-stop productivity

without compromising quality

ECNC 10080 M

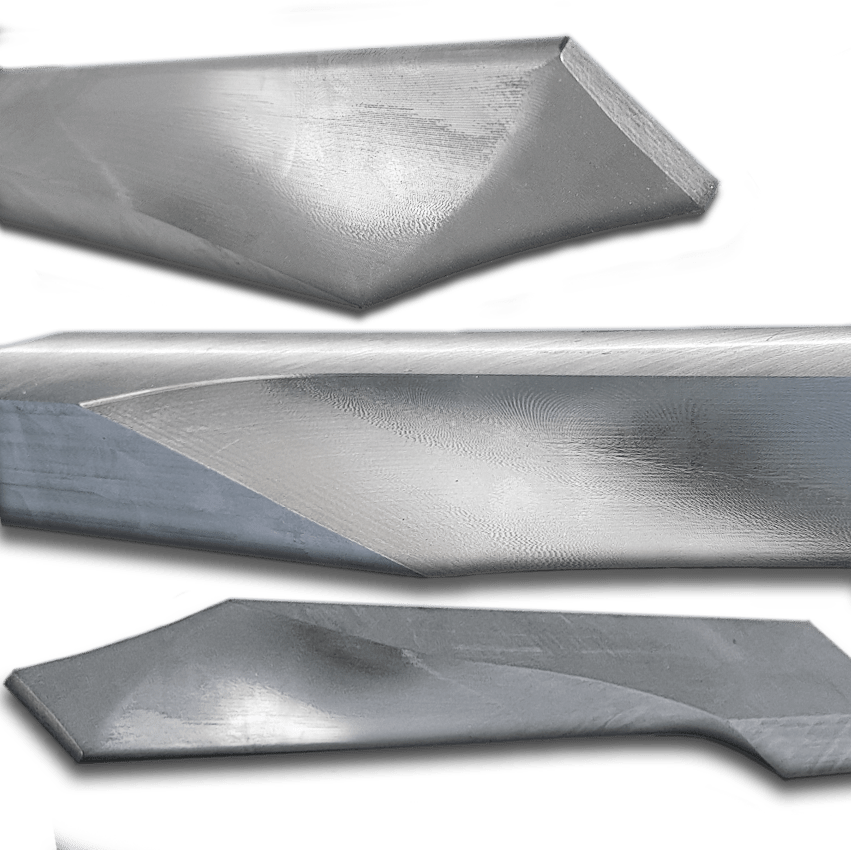

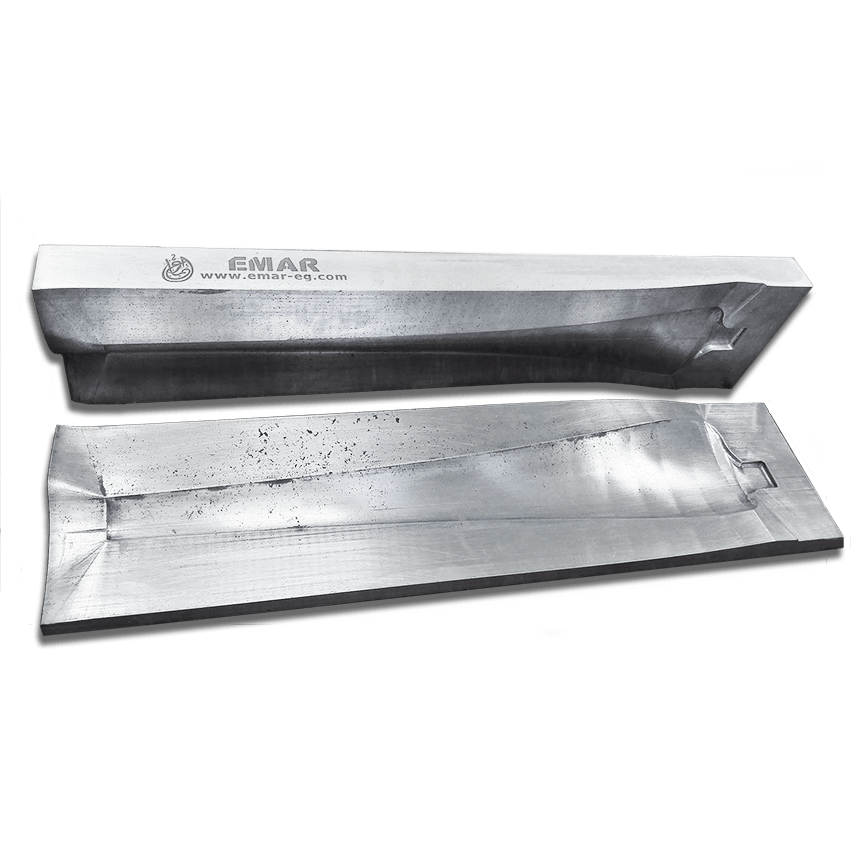

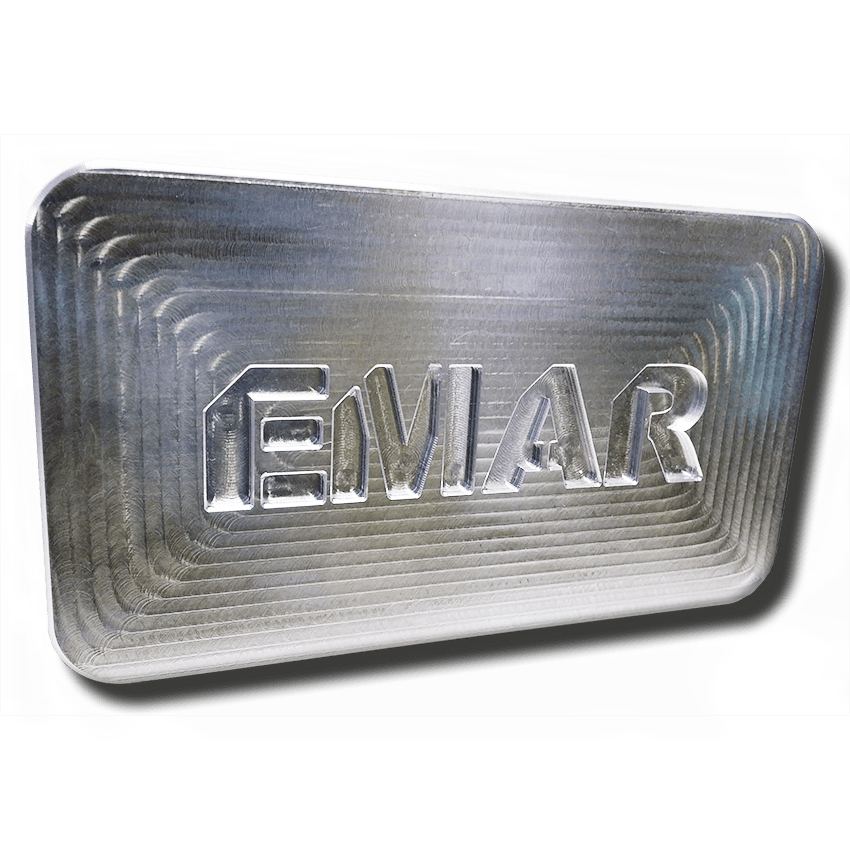

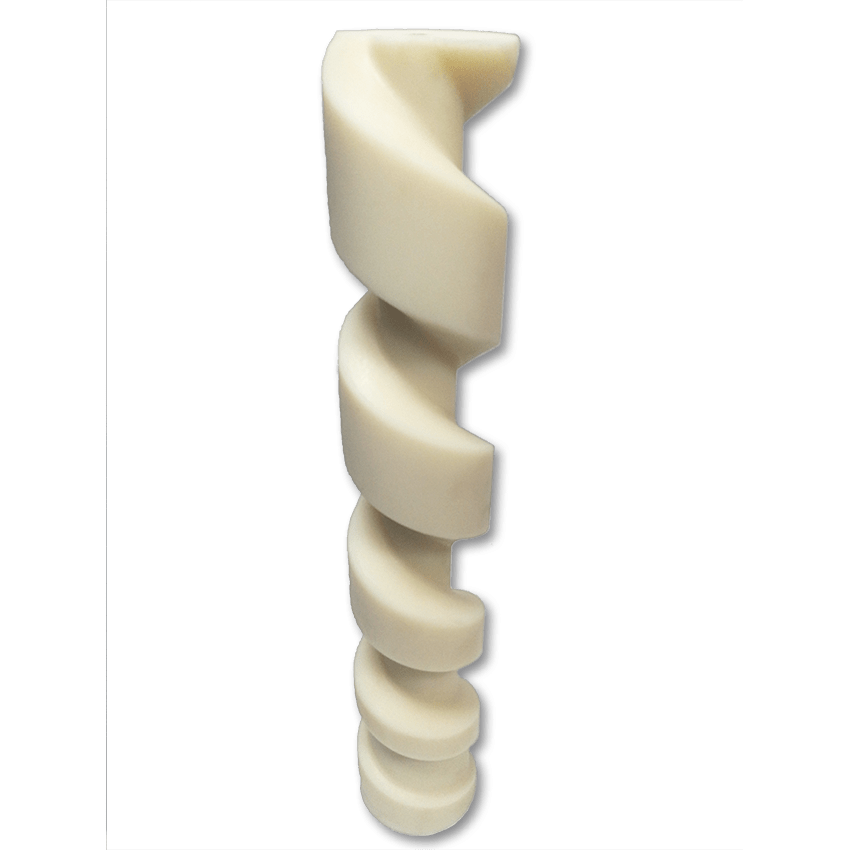

SOFT-METAL MILLS

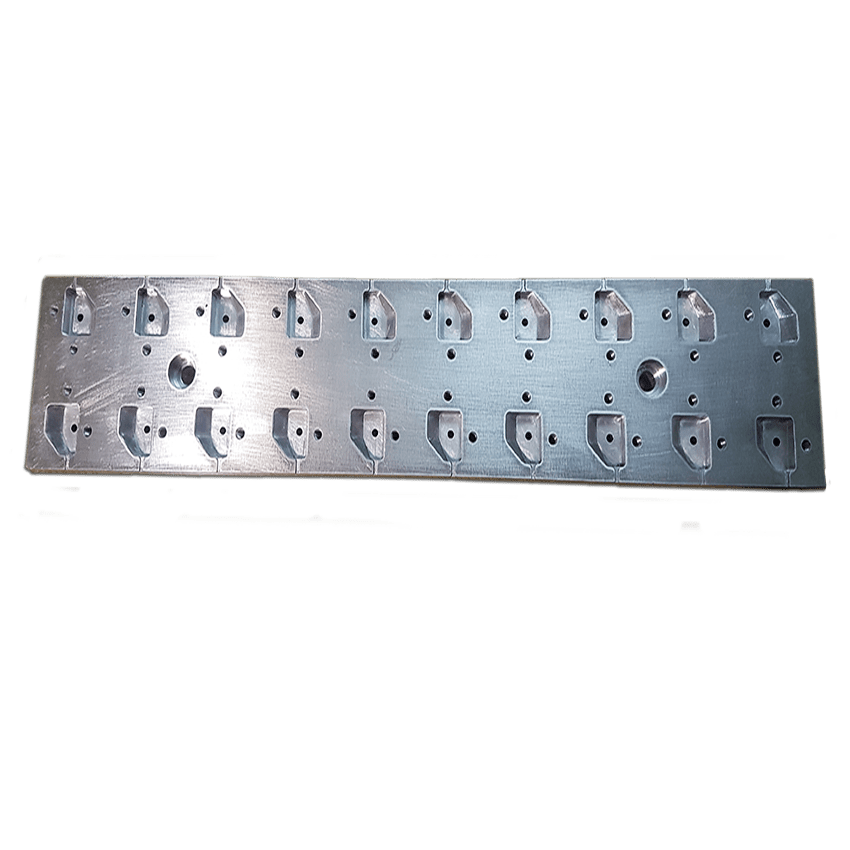

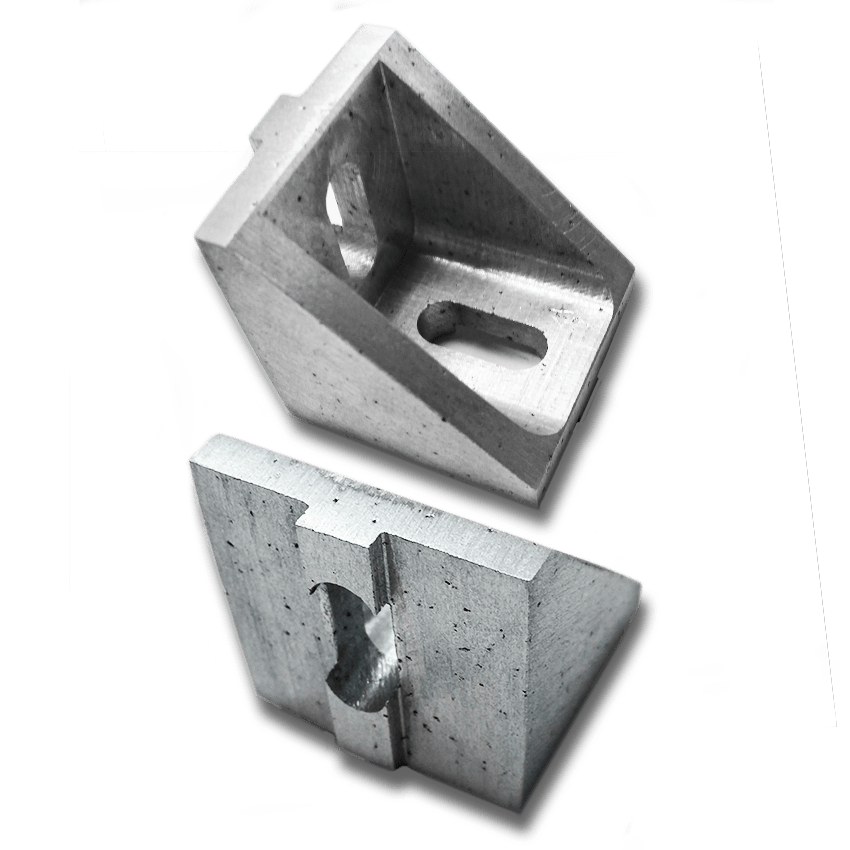

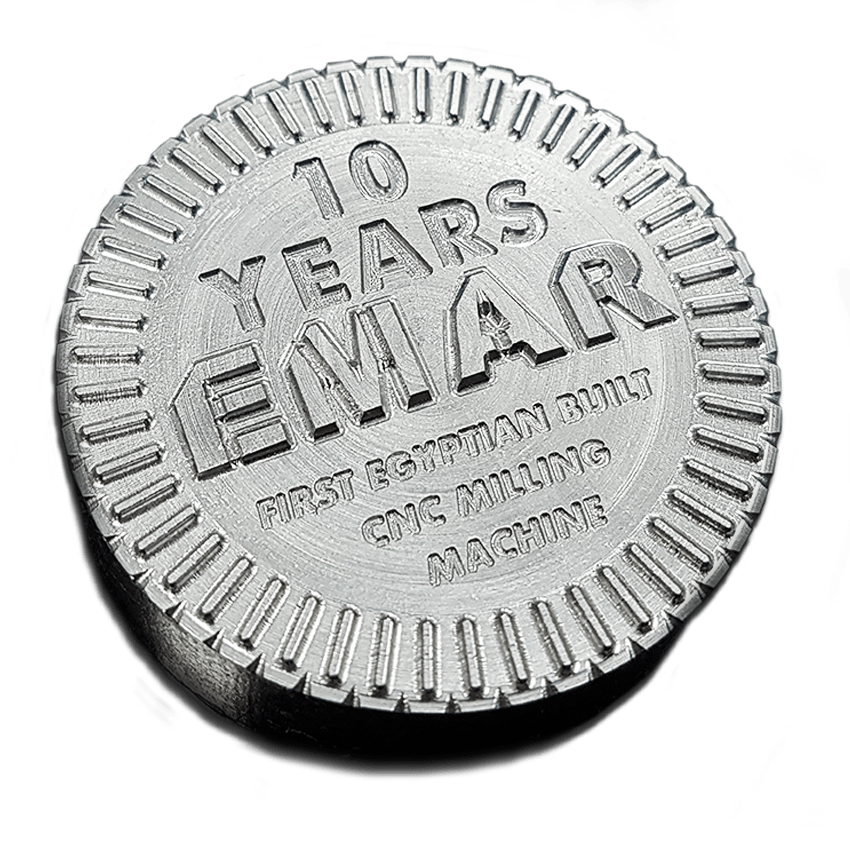

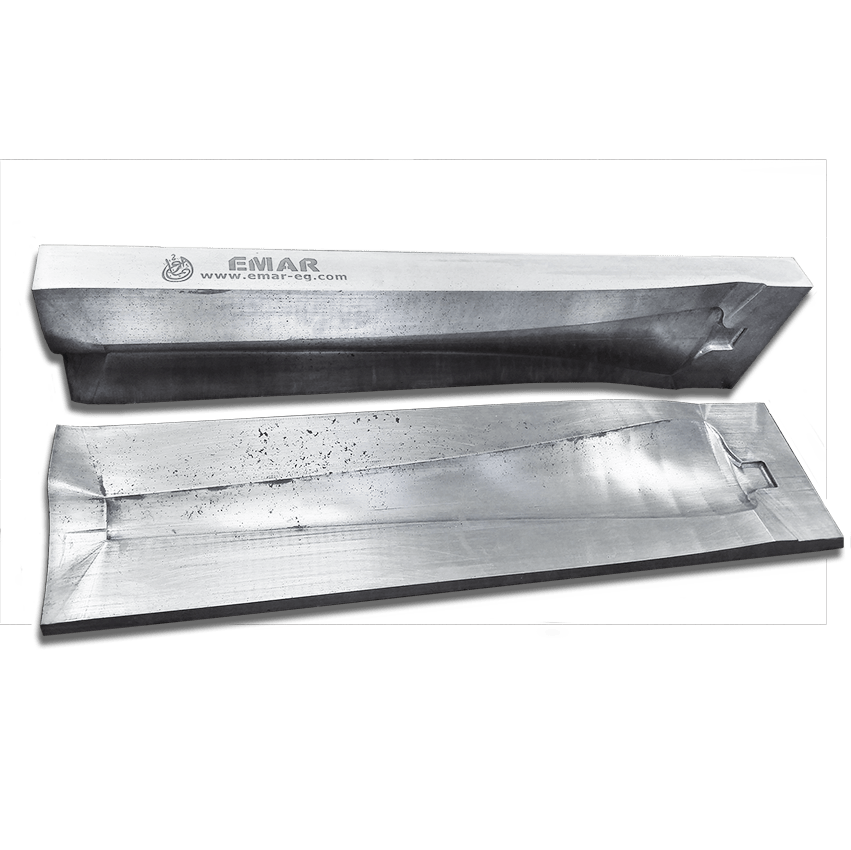

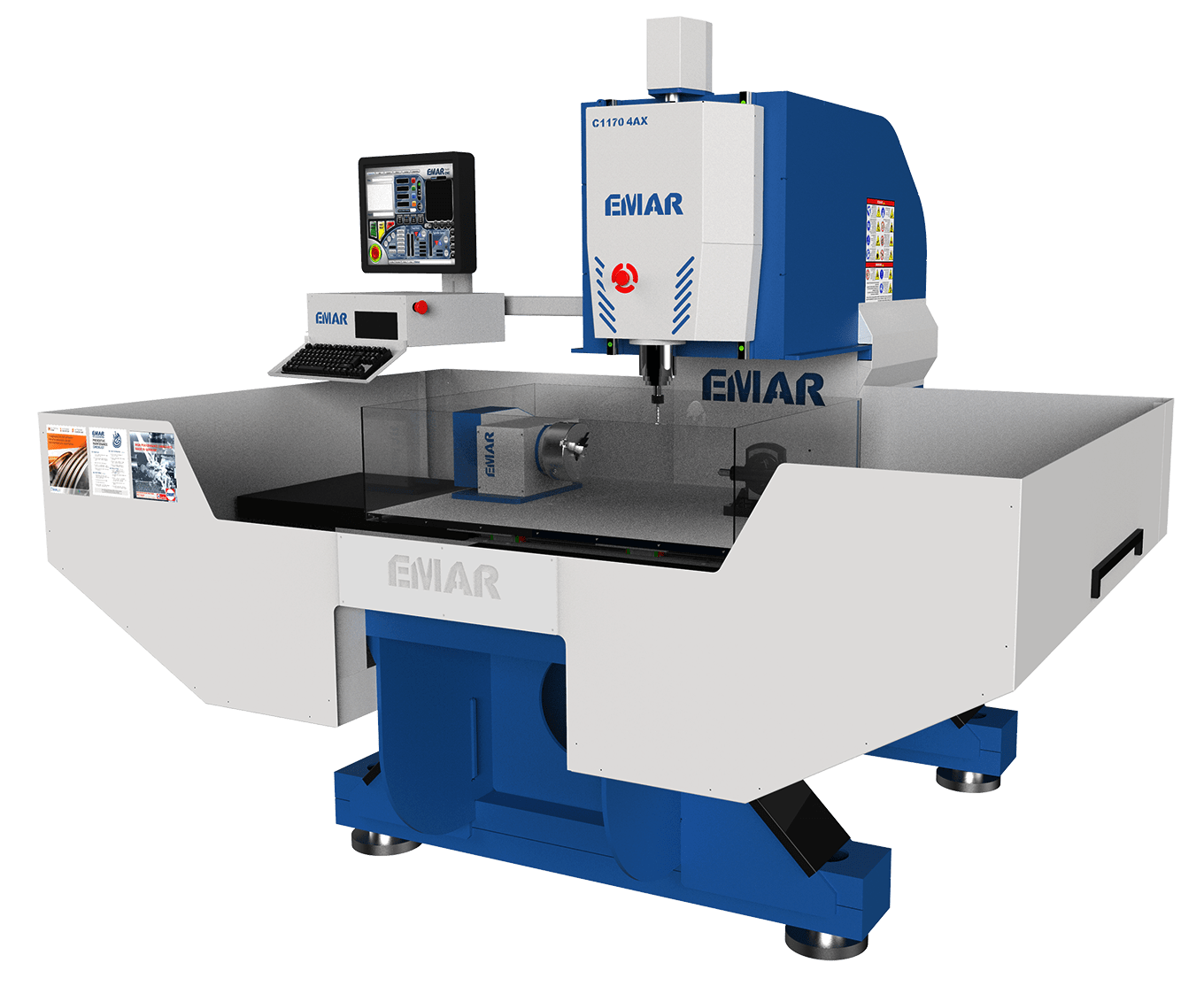

EMAR Mills are equipped with high-quality industrial milling parts and components, from liner guides, ball screws, high speed spindles, servo & stepper motors, drivers and bearings to built-up sections chassis and even electrostatic paint. Without compromising quality, this machine is unmatched in its price range.

The ECNC 10080 M components are designed for precision, longevity and with variety of options and accessories, which enables you to operate the machine in various applications without further adjustments or installations. EMAR soft-metal mills will allow you to work at full capacity around the clock, while maintaining consistent high precision without limitations.

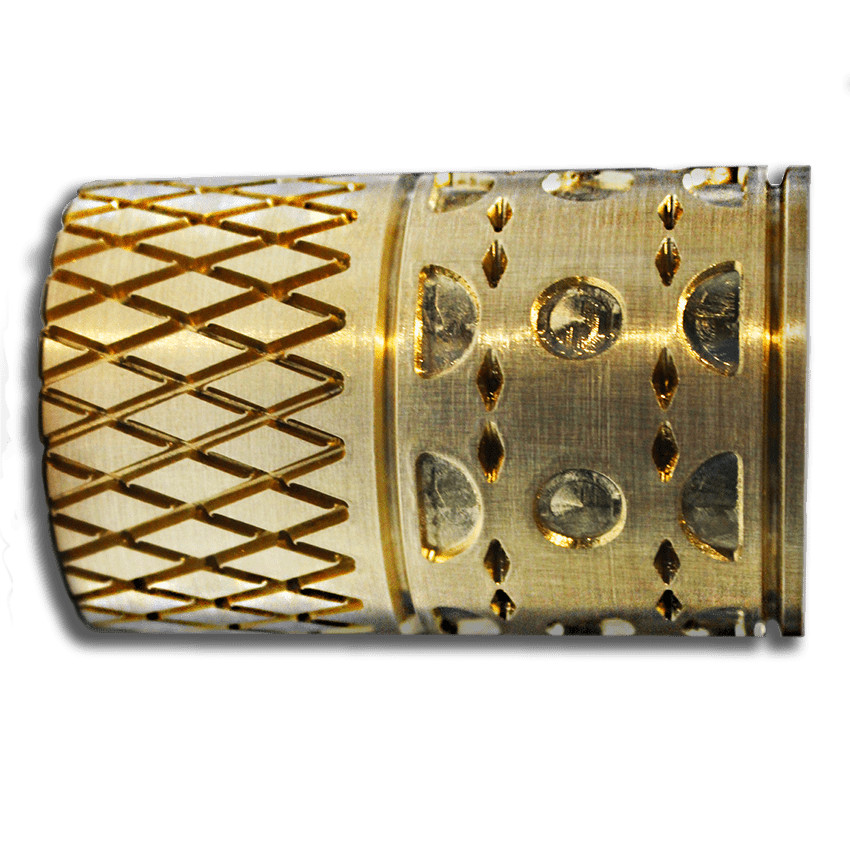

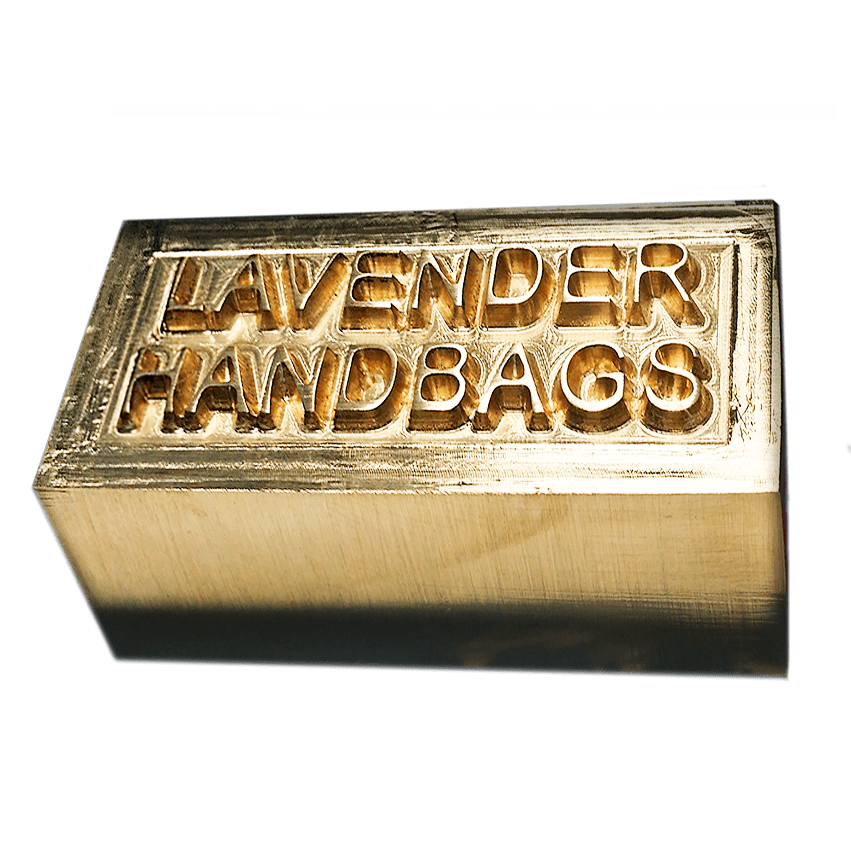

EMAR’s 4-Axis simultaneous rotary can produce complex work pieces with high precision and without the need for further rework. ECNC 10080 M offers you a very high equipment flexibility with low cost of ownership making it without doubt your ideal choice for good price – performance ratio.

ECNC 10080 M

SPECIFICATIONS

| Dimensions (W x D x H) |

2300x2400x2300 mm |

| Table size |

1000×800 mm |

| Axis travel (X,Y,Z) |

1000x800x350 mm |

| Spindle nose-table distance |

0 – 400 mm |

| Number of axes |

3 – 4 |

| Max tool diameter |

12 mm |

| Spindle type GDZ/HQD |

water cooled |

| Pmax ~ speed Max. |

5.5 kW 24,000 rpm |

| Table type / Max load |

Flat bed / 300 kg |

| Control |

Mach-3 |

| Chassis |

Built-up section |

| Weight |

2000 kg |

| Guides and bearings | HIWIN/TPI |

| Motors and drivers: | Closed Loop Hybrid Stepper Servo Motors |

| High performance poly-phaser stepper motors | |

| Lead Shine Micro stepping Driver | |

| Suitable for | Dry machining / Wet processing |

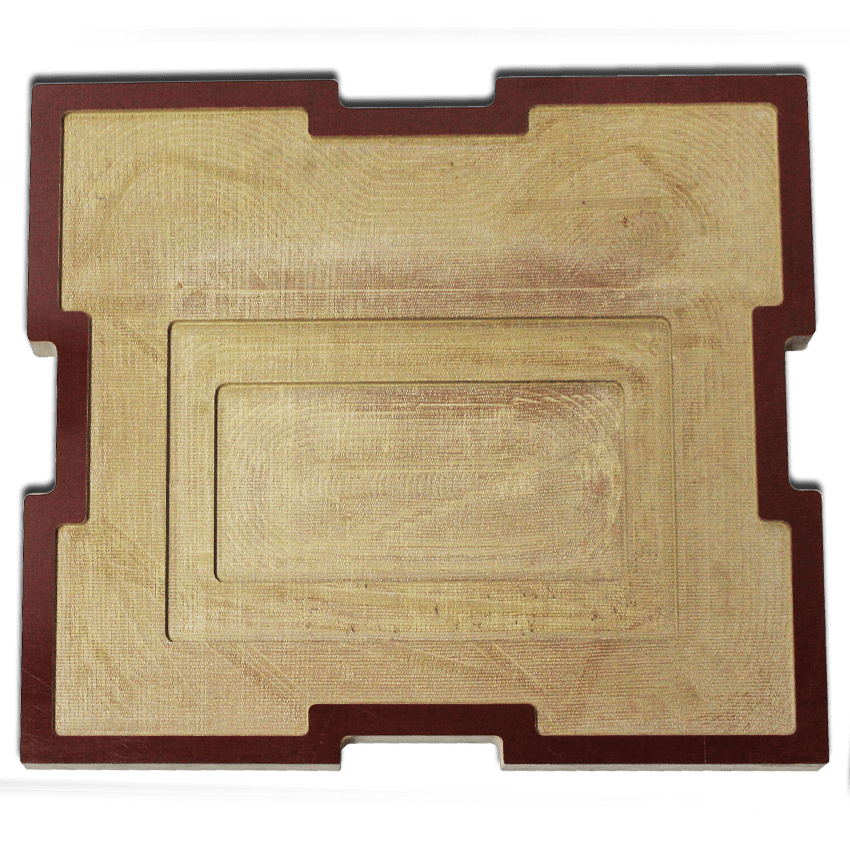

| Millable materials: | Aluminum, Copper, Brass, Artilon, Graphite, |

| Plastics, Composites, Acrylic, Wood | |

| Engravable materials: | All soft & hard metals |

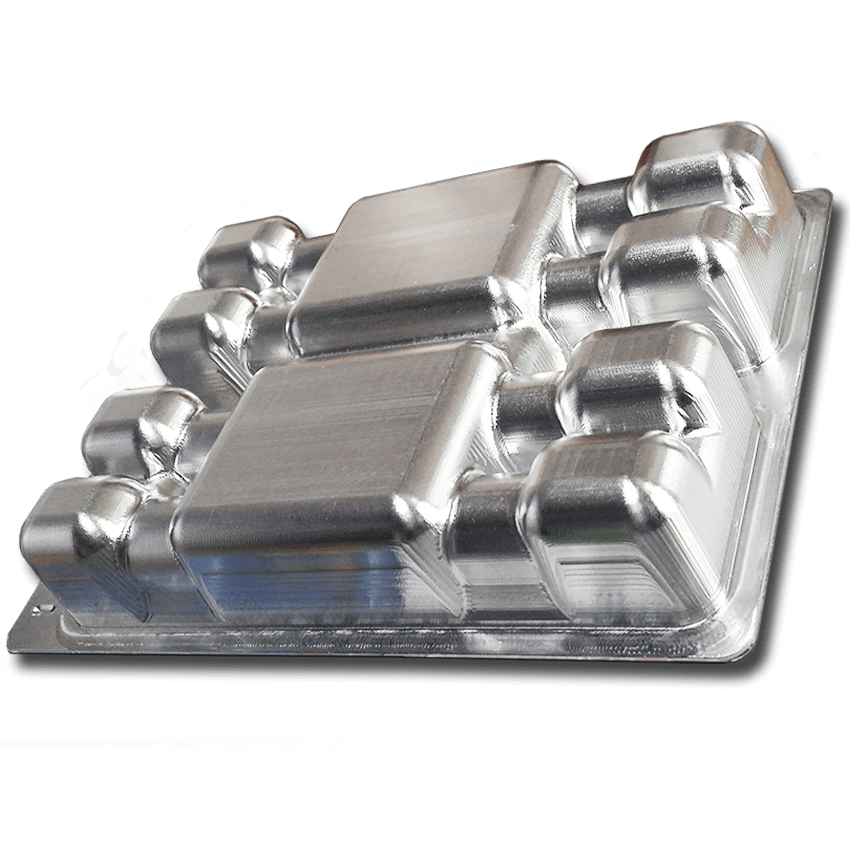

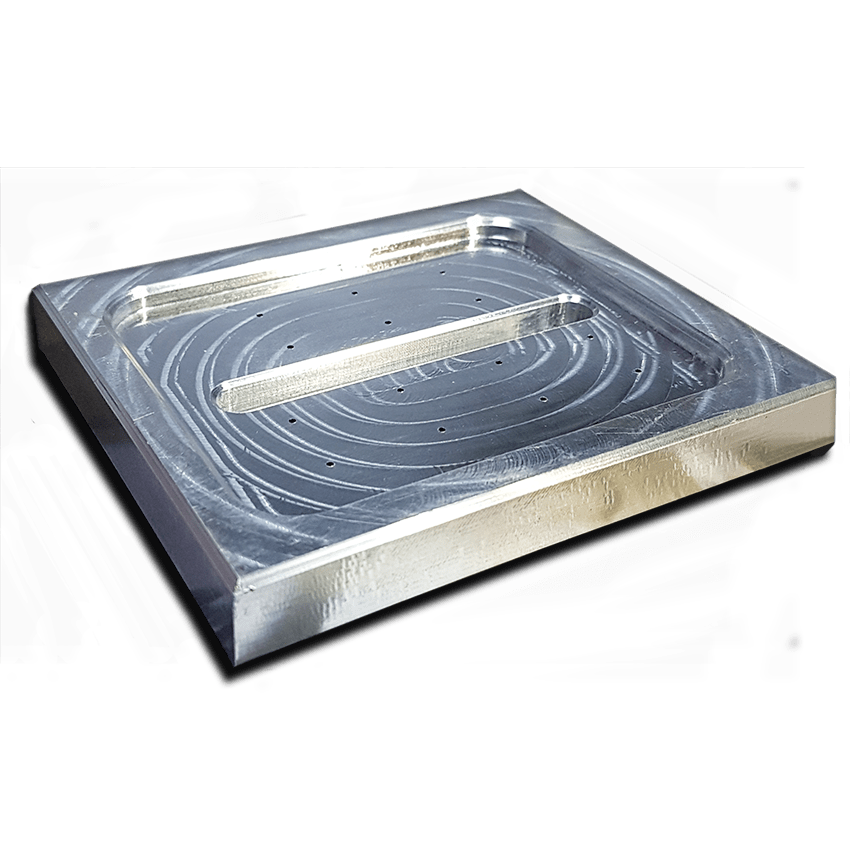

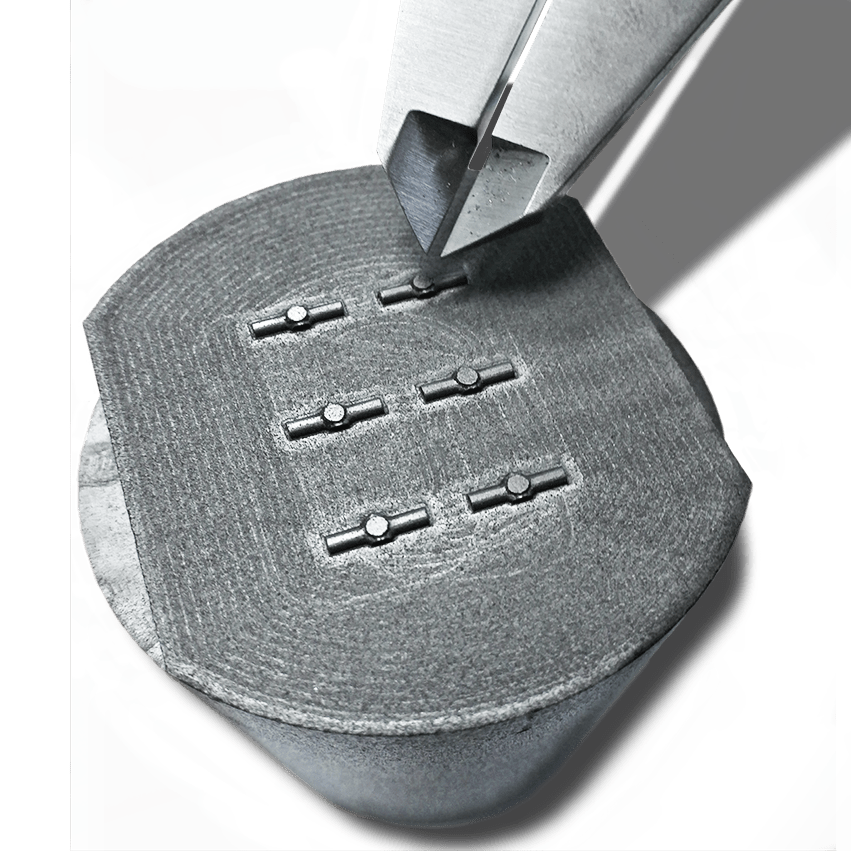

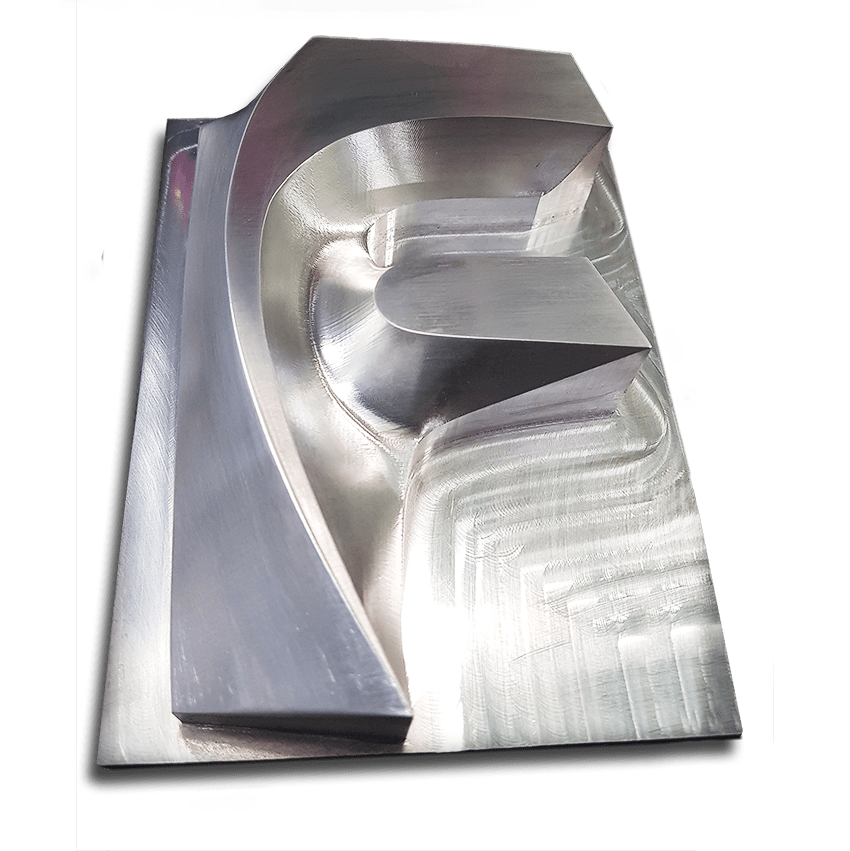

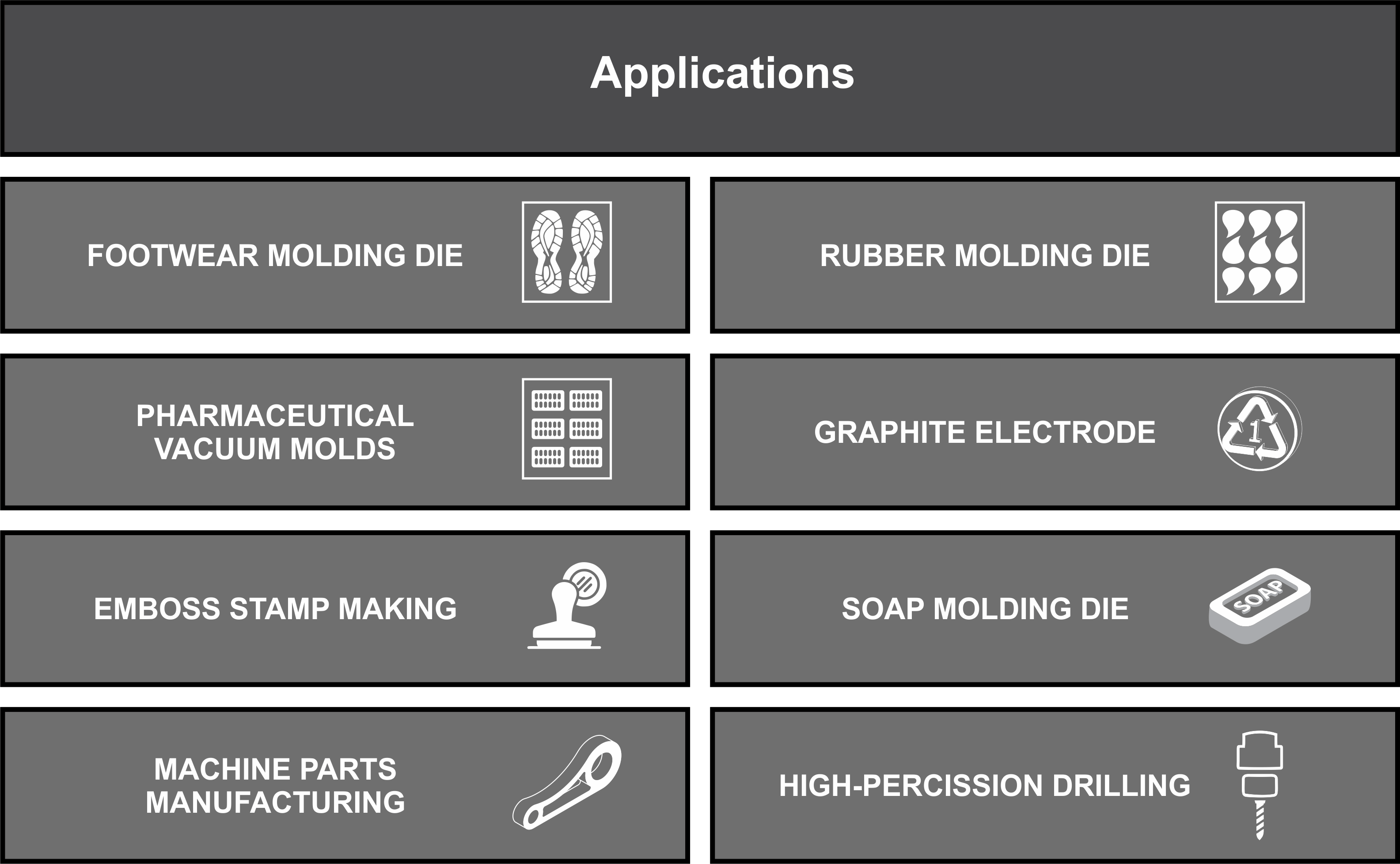

| Applications: | Footwear molds die, Rubber molds die, |

| Pharmaceutical vacuum molds, Machine parts, | |

| Graphite electrodes, Emboss stamp making, | |

| Soap molds die, High-precision drilling |