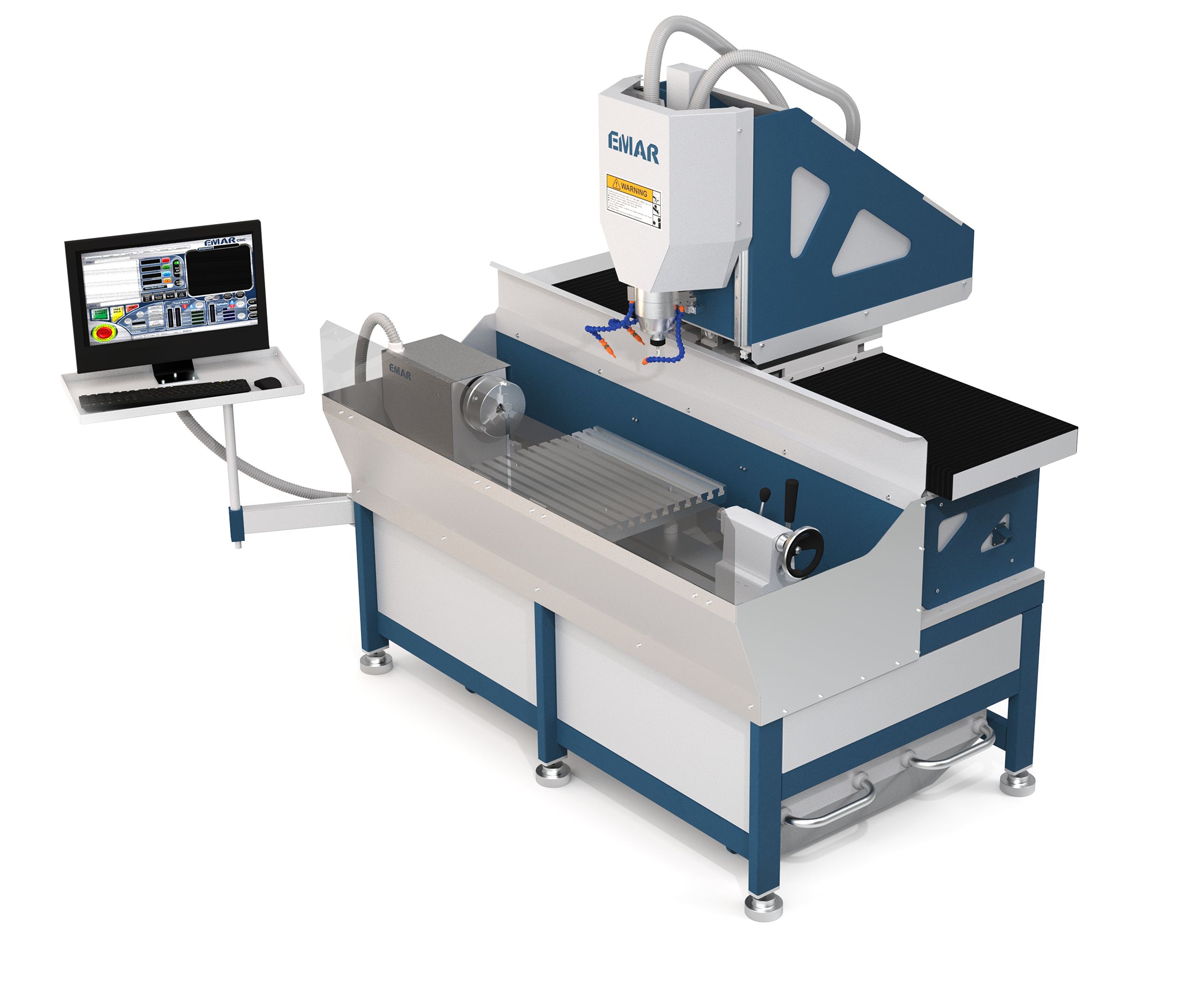

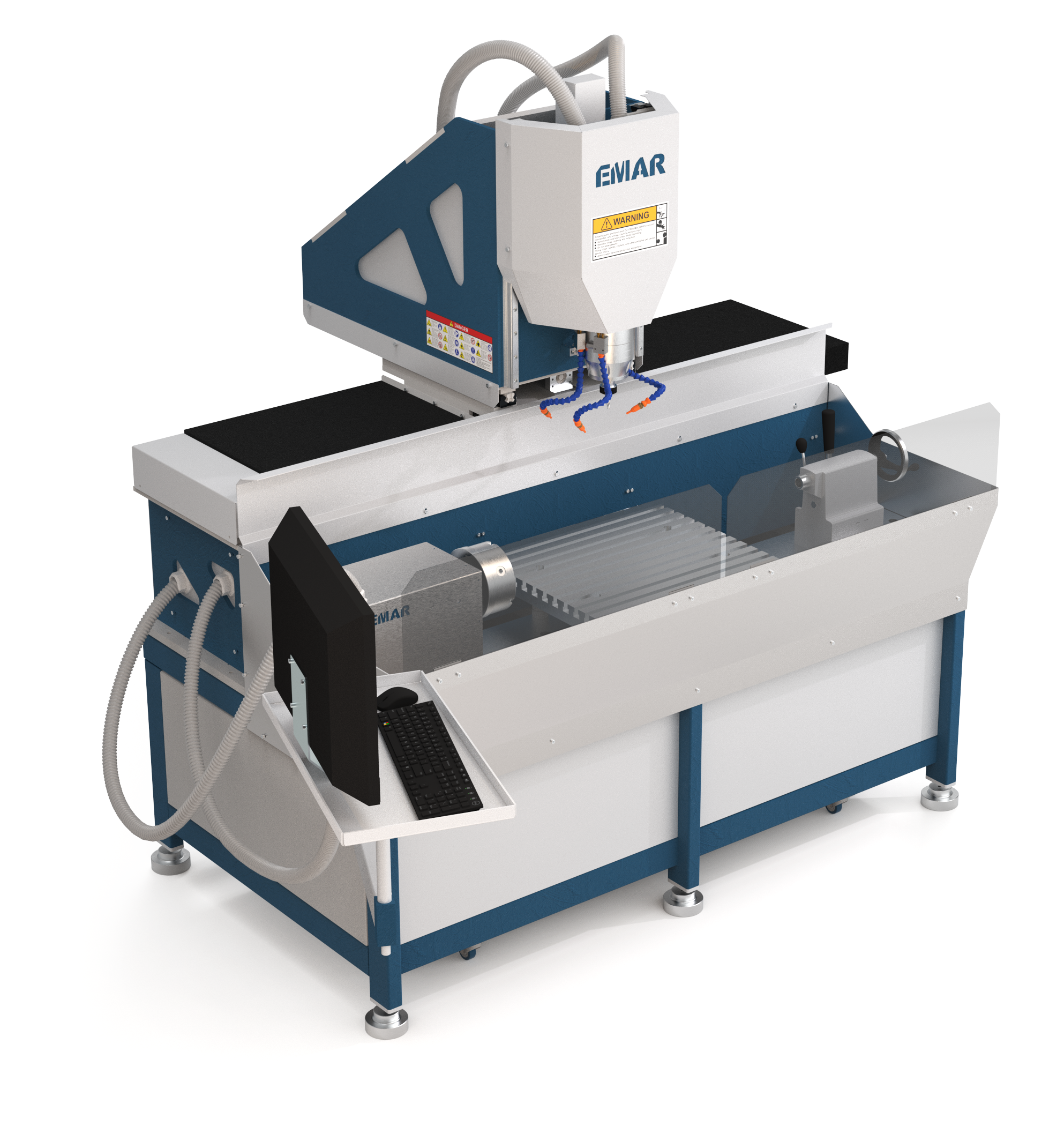

ECNC 10030 4-Axis

ROTARY MACHINE

ECNC

100300 4A

HIGHLIGHTS

MACH-3 CONTROL

Mach-3 interactive

User friendly control

BUILT-UP SECTION CHASSIS

Optimum efficiency

Highest performance to price ratio

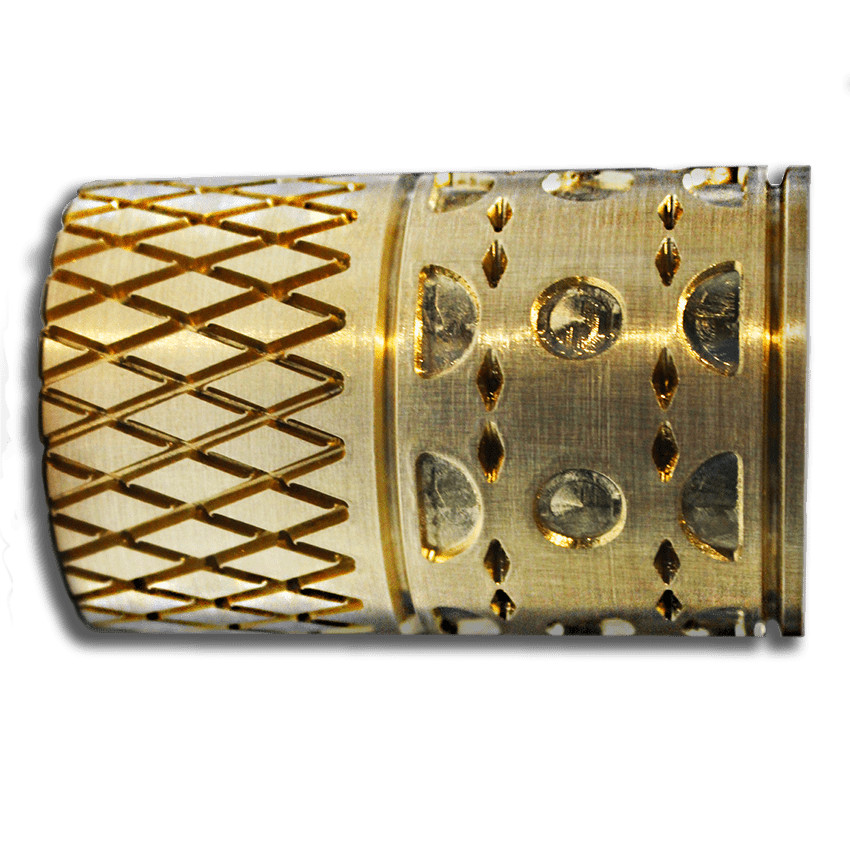

HIGH-QUALITY COMPONENTS

Leading linear and

bearing components

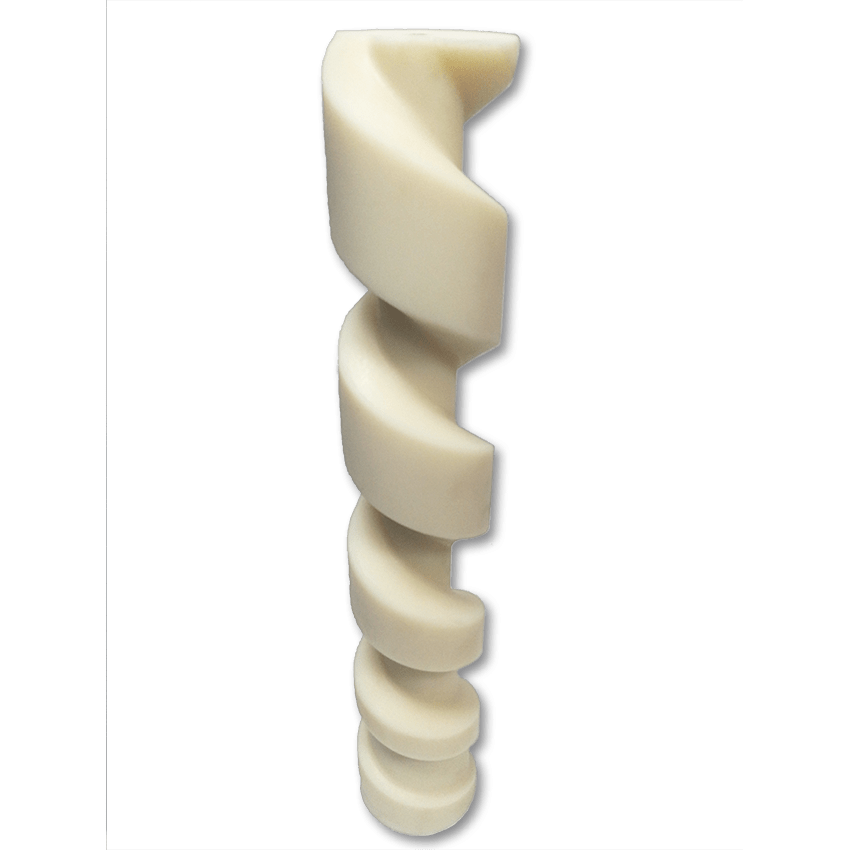

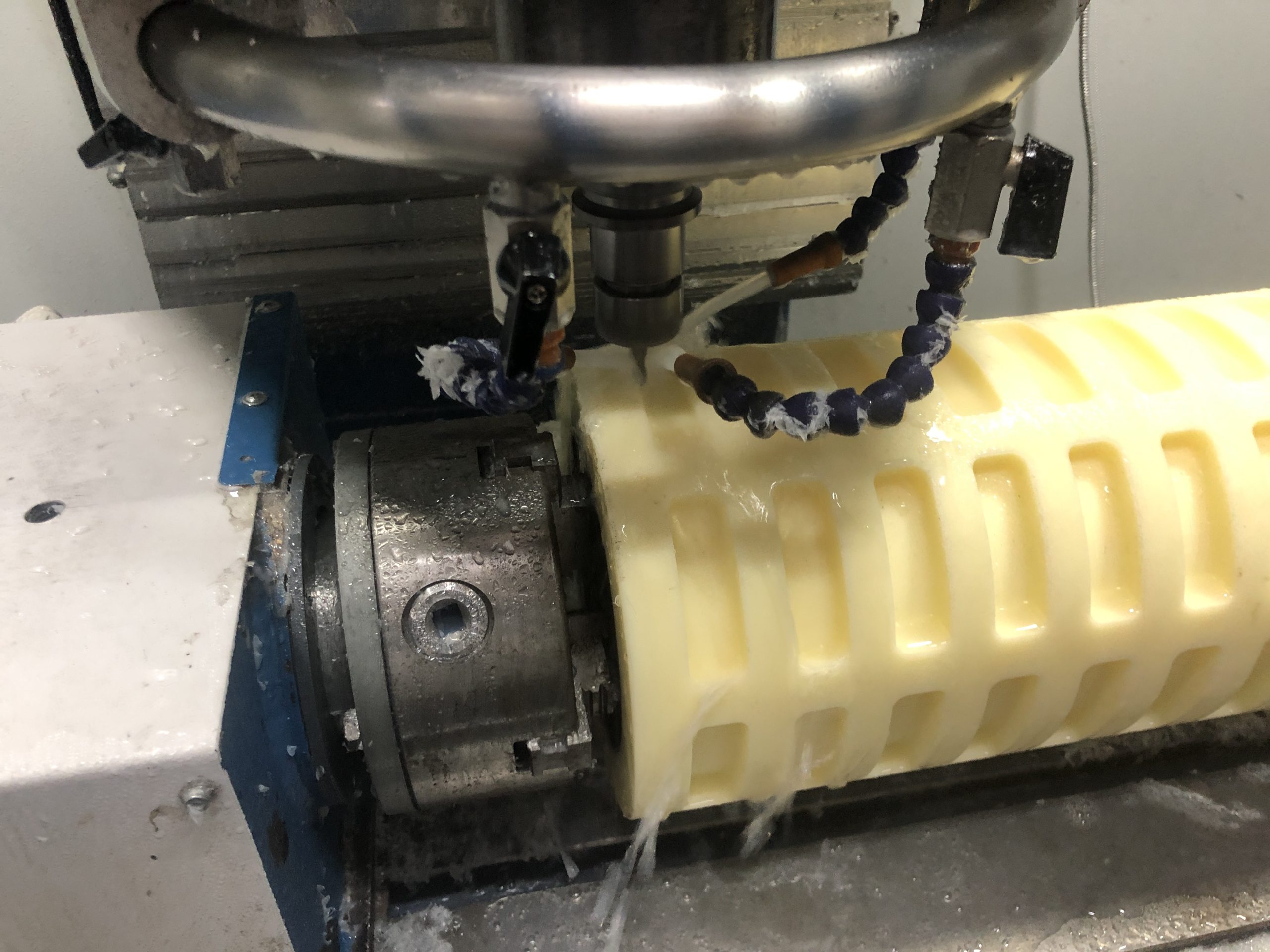

4 AXIS SIMULTANEOUS

MACHINING

High-precision

4-axis rotary

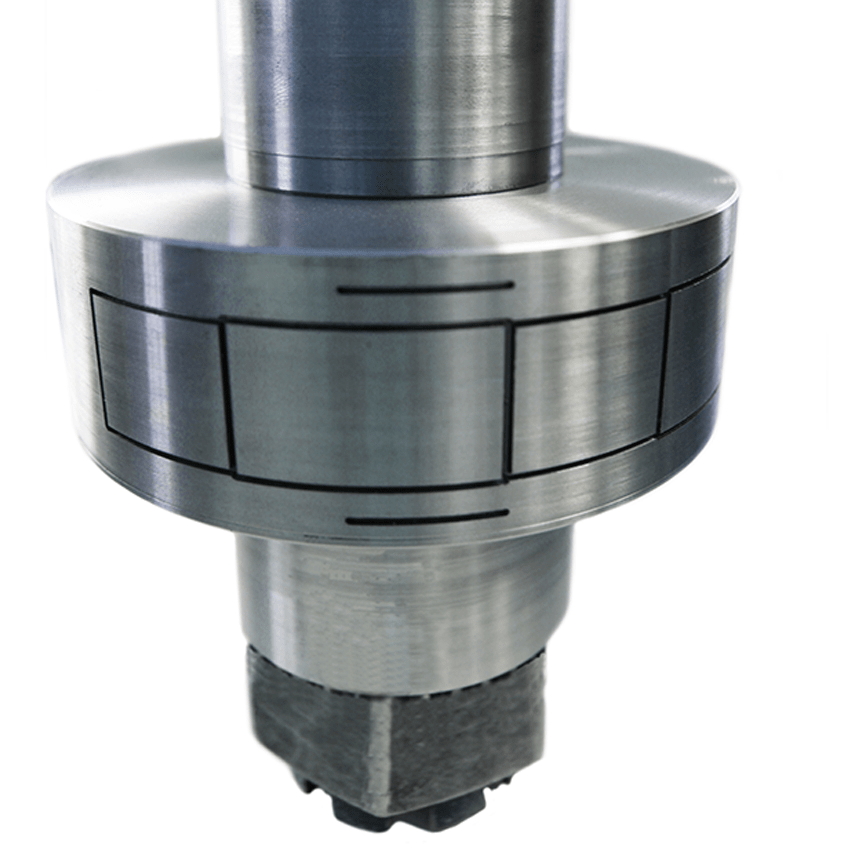

WATER

COOLED SPINDLE

3.0 kW 24k.RPM high speed spindle

for precise results with optimum finish

DURABLE

AROUND THE CLOCK

Non-stop productivity

without compromising quality

ECNC 10030 4A

ROTARY MILLS

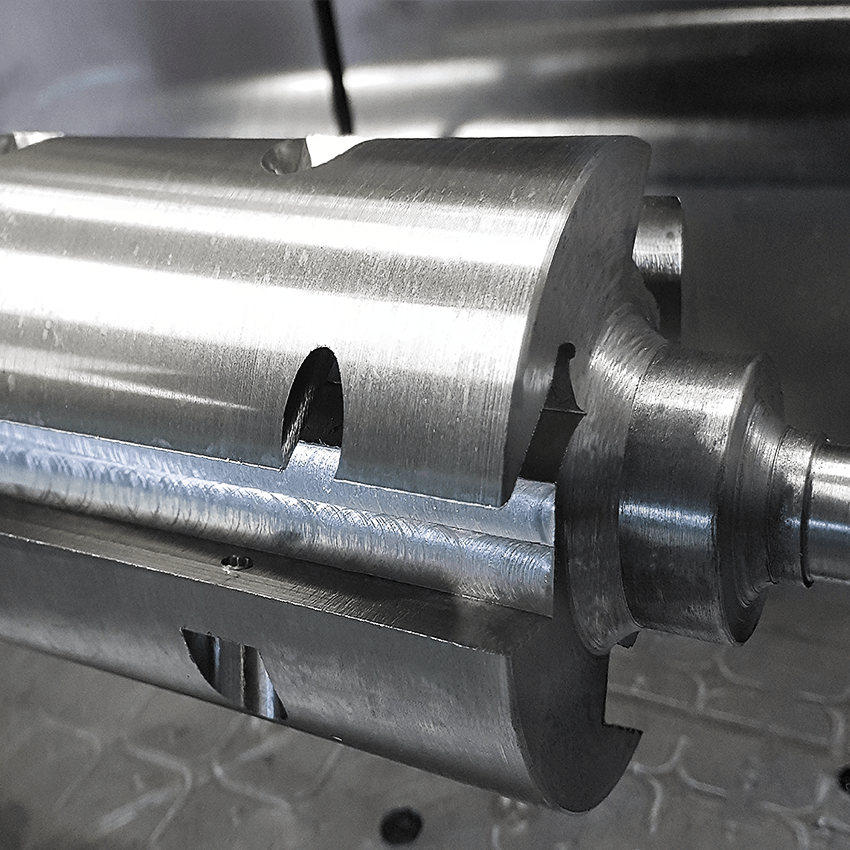

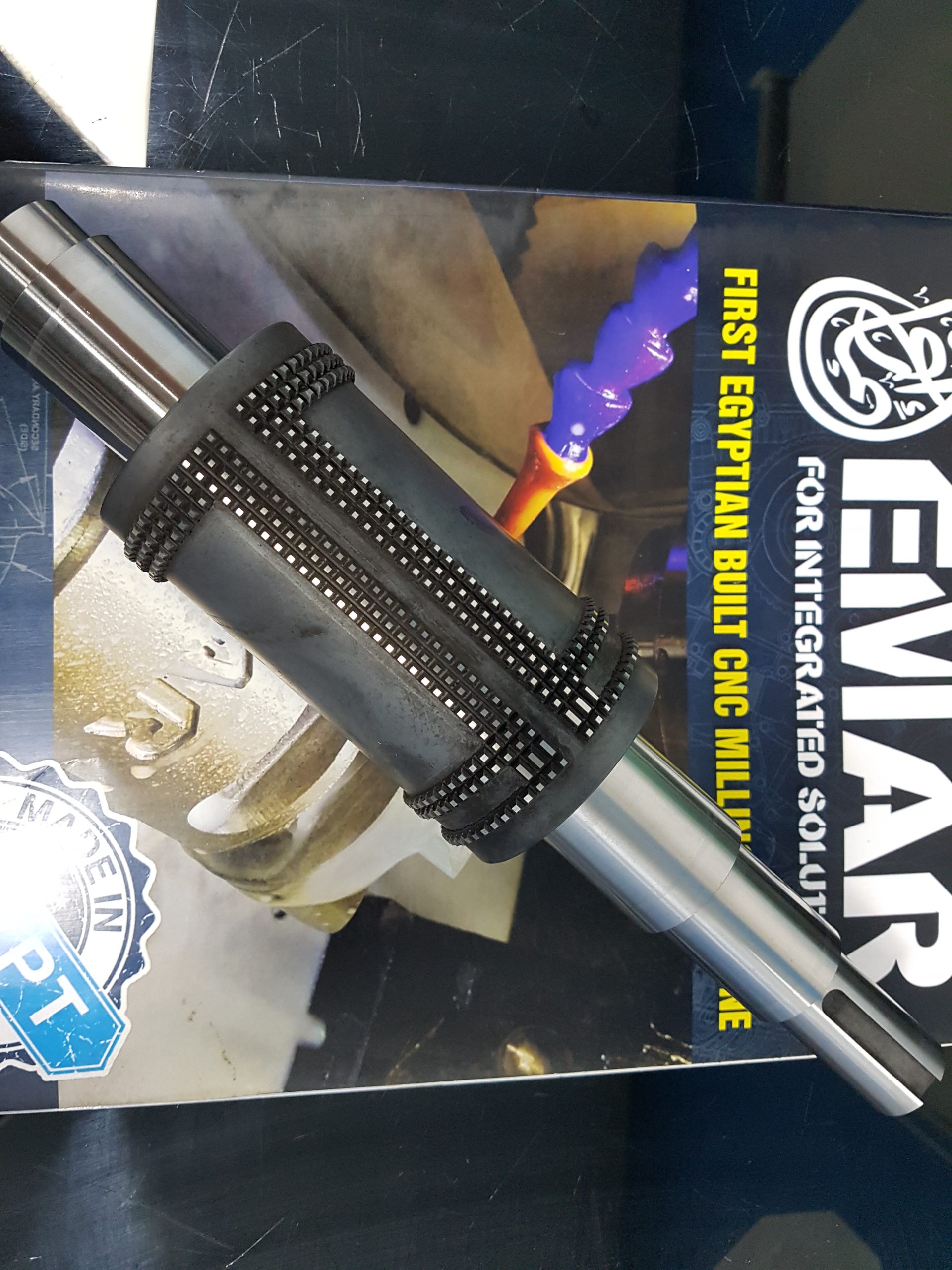

EMAR Rotaries are equipped with high-quality industrial milling parts and components, from liner guides, ball screws, high speed spindles, servo & stepper motors, drivers and bearings to built-up sections chassis and even electrostatic paint. Without compromising quality, this machine is unmatched in its price range.

The ECNC 10030 4A components are designed for precision, longevity and with variety of options and accessories, which enables you to operate the machine in various applications without further adjustments or installations. EMAR rotaries will allow you to work at full capacity around the clock, while maintaining consistent high precision without limitations.

EMAR’s 4-Axis simultaneous rotary can produce complex work pieces with high precision and without the need for further rework. ECNC 10030 4A offers you a very high equipment flexibility with low cost of ownership making it without doubt your ideal choice for good price – performance ratio.

ECNC 10030 4A relatively compact dimensions and it’s widely used CAD / CAM system applications offers a unique ratio of machine size and functionality.

ECNC

10030 4A

SPECIFICATIONS

|

Dimensions (W x D x H) |

2500 x 1500 x 2000 mm |

|

Table size |

550 x 450 mm |

|

Axis travel (X,Y,Z) |

1000 x 320 x 320 mm |

|

Rotary Axis Max. Dia. |

400 mm |

|

Number of axes |

4 |

|

Max tool diameter |

12 mm |

|

Spindle type GDZ/HQD |

water cooled |

|

Pmax ~ speed Max. |

5.5 kW 24,000 rpm |

|

Max load |

200 kg Supported |

|

Control |

Mach-3 |

|

Chassis |

Built-up section |

|

Weight |

1,500 kg |

|

Guides and bearings |

HIWIN/TPI |

|

Motors and drivers: |

Closed Loop Hybrid Stepper Servo Motors |

|

Lead Shine Micro stepping Driver |

|

|

Suitable for |

Dry machining / Wet processing |

|

Millable materials: |

Aluminum, Copper, Brass, Artilon, Graphite, |

|

Plastics, Composites, Acrylic, Wood |

|

|

Engravable materials: |

All soft & hard metals |

|

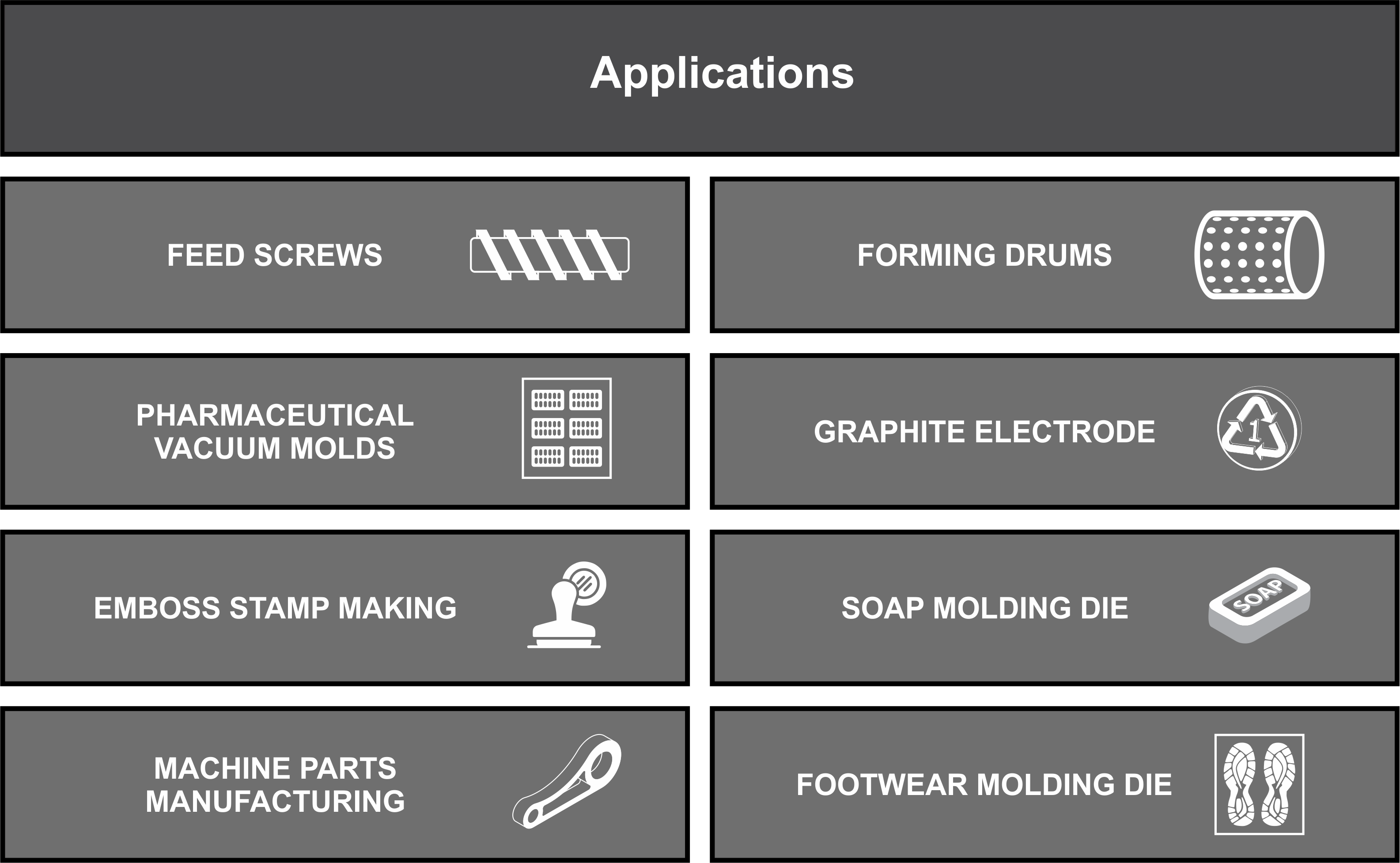

Applications: |

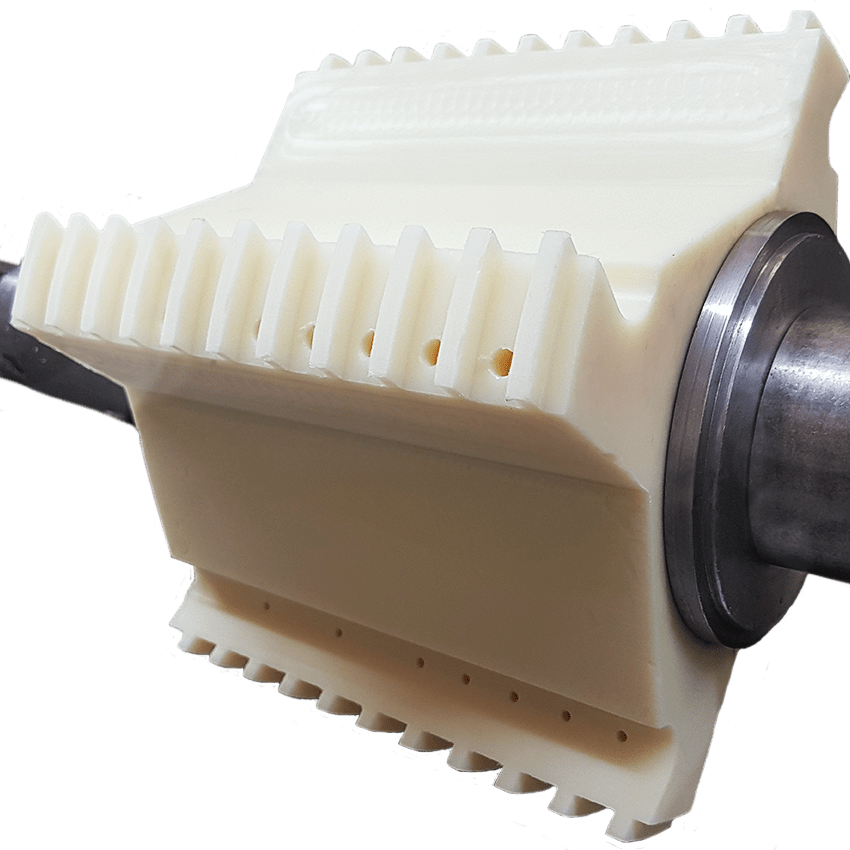

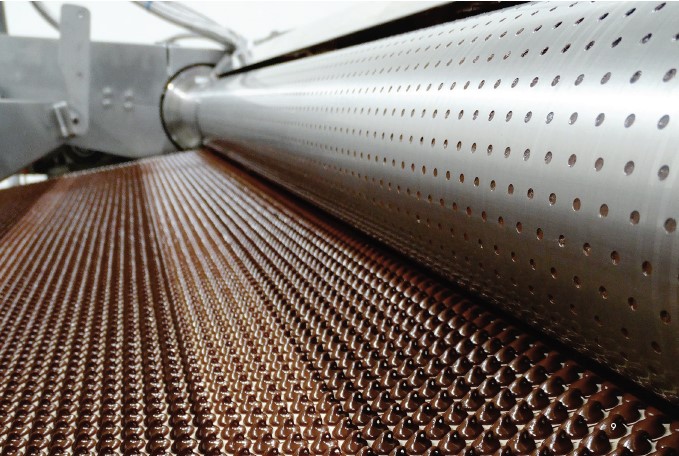

Feed Screws, Forming Drums, |

|

Pharmaceutical vacuum molds, Machine parts, |

|

|

Graphite electrodes, Emboss stamp making, |

|

|

Rubber molds die, Soap molds die |